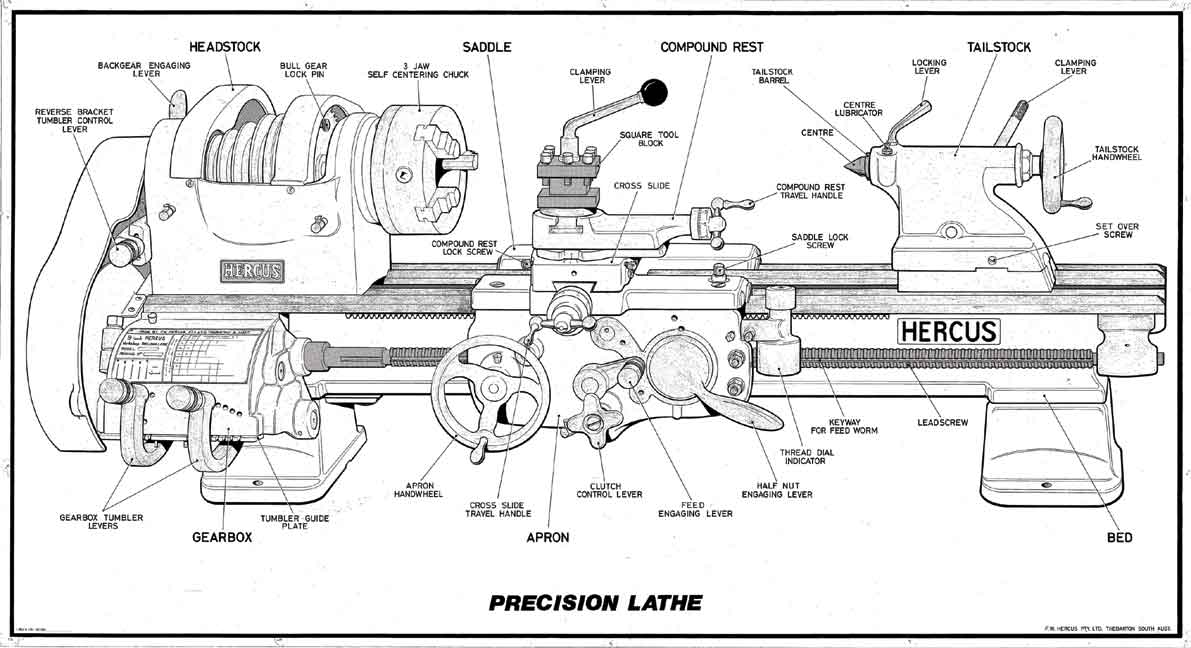

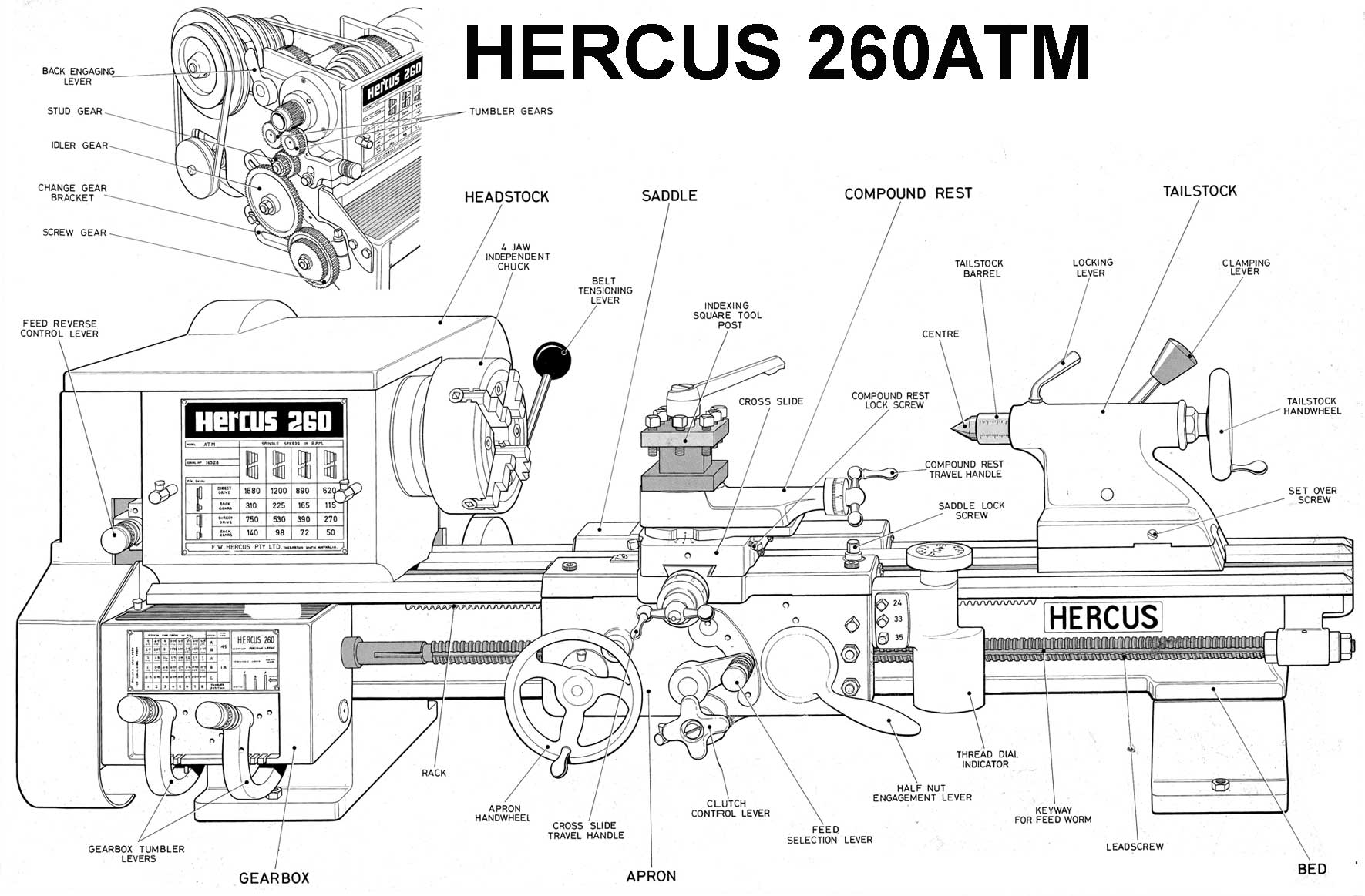

Identify your Lathe and it's parts

| The Complete list of lathes is not completed yet and is an ongoing project if you can not identify your lathe please feel free to contact us |

Letters in serial number and models explained

A = gearbox model with power feed apron

B = power feed apron no gearbox

C = base model, no gearbox or power feed apron

D = double drive shaft, leadscrew for thread cutting and driveshaft for turning

F = fast (high speed model with roller bearing countershaft}

G = geared head model (260 models only)

H = hardened bed

L = long 49" bed (standard length 40")

M = metric model (all others are imperial)

N = instrument version ( I take it this is the high precision model)

R = tapered roller bearing headstock (9" models)

T = belt drive version ( only used on the 260)

U = under bench drive. (Craftsman models)

V = Bit of a guess with this one but I think it refers to 110v 60hz electrics as they all seem to be Canadian exported machines. The "V" referring to voltage

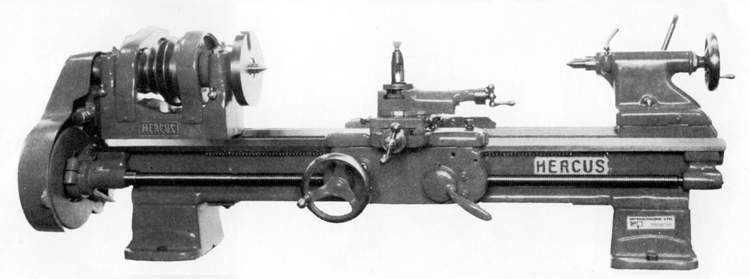

Identifying the Hercus 9" (Inch) Series

Range of Hercus 9" (Inch) Lathes

The standard range of Hercus lathe is made in 3 basic models, A, B & C. With the exception of feed and thread cutting mechanism all 3 models are identical. All models are available with either plain or roller bearings and standard or long bed series. The Craftsman range of lathes are also avaliable on Models A, B & C and with standard or long bed series. Craftsman machines are made with roller bearings only and feature an enclosed headstock with underneath drive from a drive unit built in to a cabinet base.

The power feed apron provides powered feeds both along the bed and across through a worm drive and friction clutch. Power is transmitted through a spline machined along the leadscrew, leadscrew threads being used only for screw cutting. A built-in safety device prevents simultaneous engagement of halfnuts and power feeds.

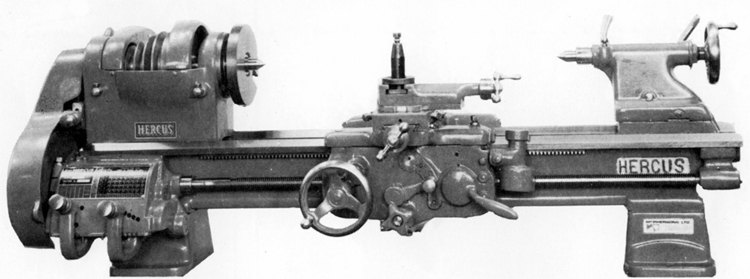

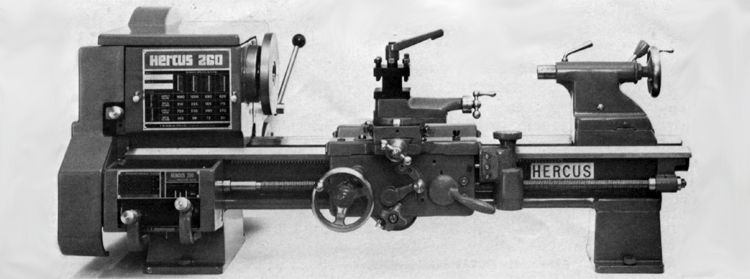

The Model B lathe (above) has an automatic power feed apron but is not fitted with a gearbox. Power feed rates and screw thread pitches are obtained through a set of conventional pick off change-wheels, arranged in accordance with an index chart on the lefthand end cover. The set of change-wheels provided with B model lathes comprises 13 change gears, one idler and two compound idler gears, the larger gears being cast iron and the smaller ones steel.

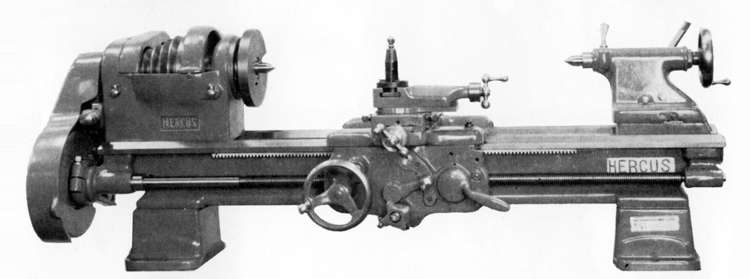

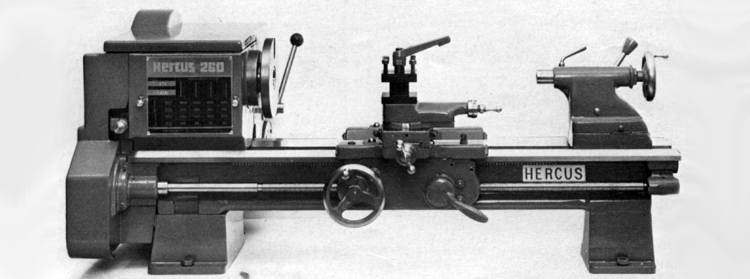

The model C lathe (above) has plain apron and is not fitted with a gearbox, thus considerably simplifying the machine. A set of conventional pick off change gears, together with an index chart, give a screw cutting range from 4 to 160 T.P.I. and provides 14 feed rates through the leadscrew. No power cross feed is provided. The set of change-wheels provided with C model lathes comprises 13 change gears, one idler and two compound idler gears, the larger gears being cast iron and the smaller ones steel.

The Model A has a quickchange gearbox and power feed apron. The gearbox enables a quick and simple selection of screw threads or feed rates while the apron may be used to engage either the leadscrew thread for screw-cutting or drive the leadscrew keyway for power feed, the engaging lever can select either longitudinal or cross feeds and is interlocked with the thread halfnuts to prevent simultaneous engagement.

The Model B has the same power feed apron but is not fitted with the quick change gearbox. Screw threads and feed rates are obtained by using a set of change gears.

Hercus 260T - The Model C (CTM)

The Model C is the simplest version having a plain apron which engages the leadscrew thread for screw cutting and also for a limited range of longitudinal feeds only. Screw threads and feed rates are obtained by using a set of change gears.